Medical injection molding is a specialized manufacturing process that plays a critical role in producing intricate and precise components for the healthcare industry. This process ensures the mass production of medical devices with consistent quality, meeting the stringent requirements of the healthcare sector. In this article, we will explore the medical injection molding production process, highlighting the key stages that contribute to the creation of high-quality medical products.

1. Design and Prototyping:

The medical injection molding production process initiates with a comprehensive design phase. Engineers and designers collaborate to create detailed 3D models of the medical components, considering aspects like material selection, part geometry, and regulatory compliance. Prototyping follows the design phase, allowing for testing and refining the product before moving to large-scale production. This step is crucial in ensuring the final product meets required specifications and quality standards.

2. Mold Design and Fabrication:

Following the design approval, the next stage involves the design and fabrication of the mold. The mold is a precision tool used to shape the molten plastic into the desired form. Mold design encompasses crucial decisions such as determining the cavity shape, parting lines, and overall mold structure. High-quality materials like steel or aluminum are used to ensure the mold’s durability and precision. The intricacy of the mold is paramount for achieving accurate and consistent results in the injection molding process.

3. Material Selection:

The selection of the appropriate material is a key determinant of the success of the medical injection molding production process. Medical-grade plastics are commonly chosen, meeting strict biocompatibility and regulatory standards. Material selection is influenced by factors like the intended use of the medical device, sterilization requirements, and specific properties required for the final product. The chosen material must possess the necessary strength, flexibility, and biocompatibility.

4. Injection Molding Machine Setup:

With the mold in place, the injection molding machine is set up for production. This step involves configuring machine parameters such as temperature, pressure, and injection speed. The machine is loaded with the selected injection molding material in the form of pellets. Proper machine setup ensures that the injection molding process is calibrated for consistent and high-quality production.

5. Injection:

The injection phase is where the actual molding process takes place. The injection molding machine injects the molten plastic material into the mold cavity at high pressure. The plastic fills the mold, taking on the shape of the cavity and any features incorporated into the mold design. Precision is crucial during this step to ensure the molten plastic reaches all areas of the mold, creating a uniform and accurate part.

6. Cooling:

Once the mold cavity is filled, the molten plastic is allowed to cool and solidify. The cooling phase is crucial in determining the final structure and properties of the molded part. Proper cooling ensures that the part solidifies evenly, minimizing the risk of defects and improving the overall quality of the medical component.

7. Ejection:

After the cooling phase is complete, the mold opens, and the newly formed part is ejected. Ejection mechanisms, such as pins or ejector plates, carefully remove the part from the mold. The ejection process must be gentle to avoid damaging the part or the mold. The cycle then repeats, with the mold closing and the injection process beginning again for the next part.

8. Inspection and Quality Control:

Every molded part undergoes thorough inspection and quality control measures to ensure it meets the specified standards. This may involve visual inspection, measurements, and testing for material properties. Quality control is particularly crucial in the medical industry, where precision and consistency are paramount to ensure the safety and effectiveness of medical devices.

9. Post-Processing (If Necessary):

Depending on the specific requirements of the medical device, post-processing steps may be employed. This can include additional machining, assembly, or surface finishing. Post-processing ensures that the final product meets all functional and aesthetic criteria before being released for use in medical applications.

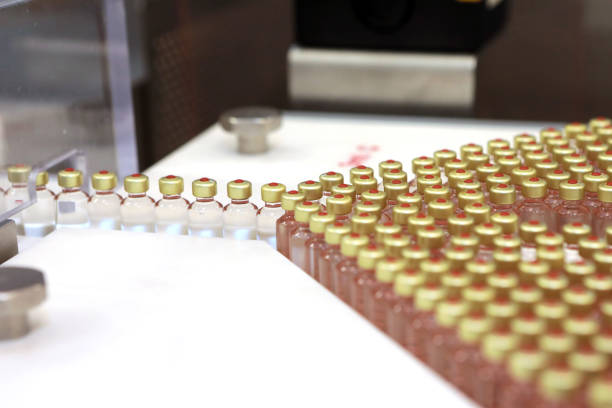

10. Packaging and Sterilization:

The final step in the medical injection molding production process involves packaging the molded components in a sterile environment. Sterilization is critical for medical devices, and the packaging must maintain the cleanliness and integrity of the parts. This step ensures that the medical components are ready for use in healthcare settings without compromising patient safety.

Conclusion:

In conclusion, the medical injection molding production process is a highly sophisticated and controlled method that ensures the efficient creation of intricate and reliable medical components. From design and prototyping to mold fabrication, material selection, and the injection molding cycle, each stage contributes to the success of the process.

The precision and efficiency of medical injection molding make it a cornerstone technology in the production of various medical applications. As technology continues to advance, the medical injection molding production process will likely see further innovations, contributing to the development of safer and more sophisticated medical devices.